Newsletters from 2003

As Yates Mill was restored, Yates Mill Associates published and mailed paper newsletters to keep supporters informed of the progress and to share historical discoveries.

Here are some articles from 2003:

- The Finley Lodge by Dick Thompson and John Vandenbergh

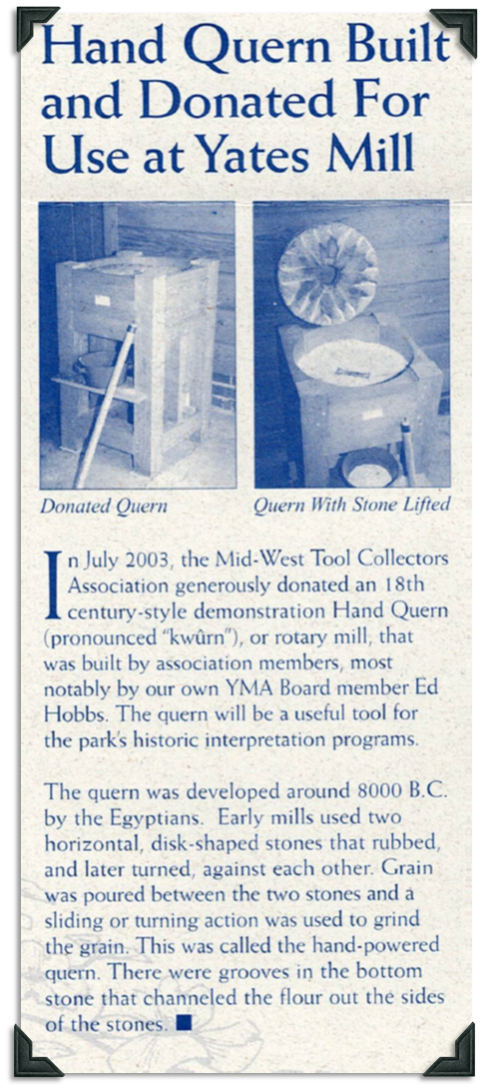

- Hand Quern Built and Donated for Use at Yates Mill

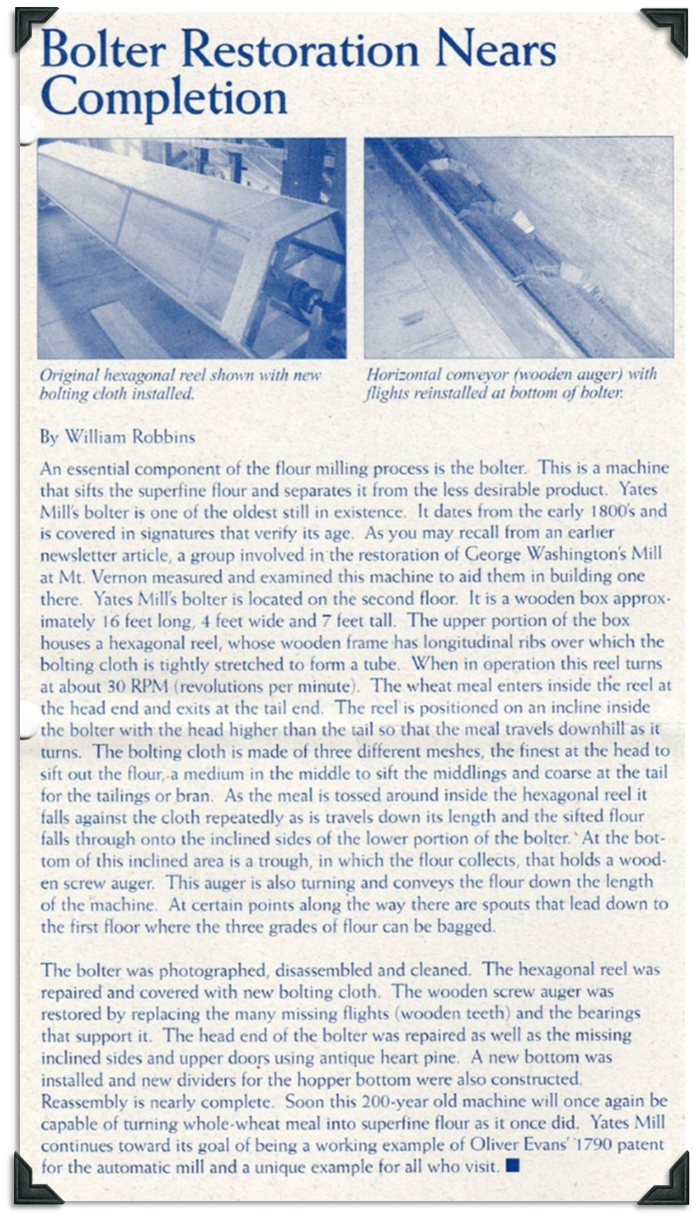

- Bolter Restoration Nears Completion by William Robbins

- Recollections of the Mill from 25 Years Ago by Donald Barnes

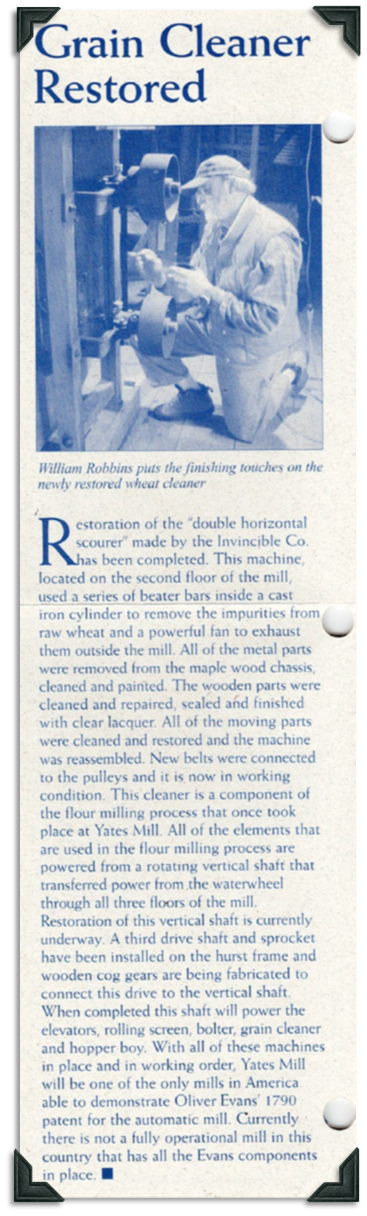

- Grain Cleaner Restored

- Researchers Visit Yates Mill

- Mill Speak Round 2

- Mill Speak Round 3

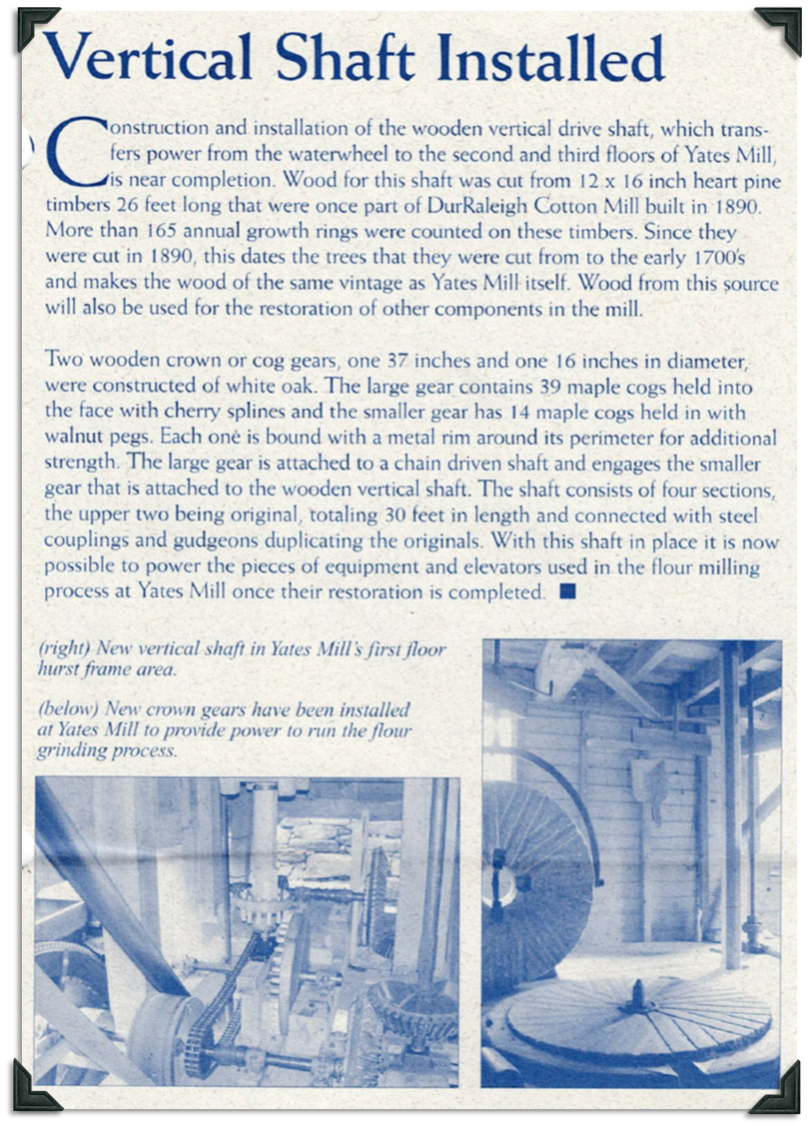

- Vertical Shaft Installed

To see more information about the history of Yates Mill and the role Yates Mill Associates played in restoring the mill, visit the A.E. Finley Center at Historic Yates Mill County Park to see displays, view artifacts, and watch videos of the mill in action.