Newsletter Articles from 2005

As Yates Mill was restored, Yates Mill Associates published and mailed a paper newsletter to keep supporters informed on the progress and share historical discoveries.

Here are some articles from 2005:

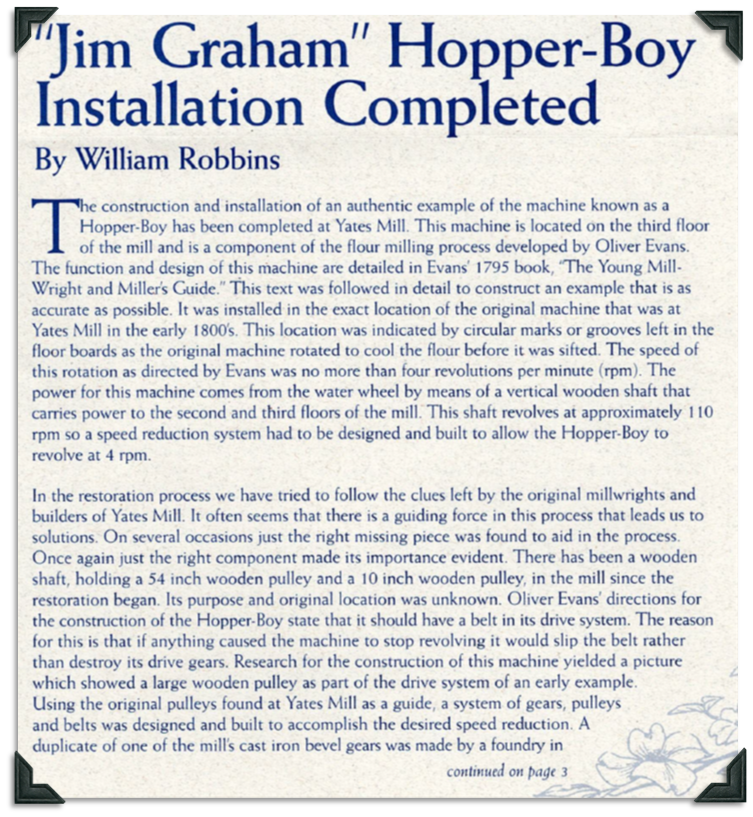

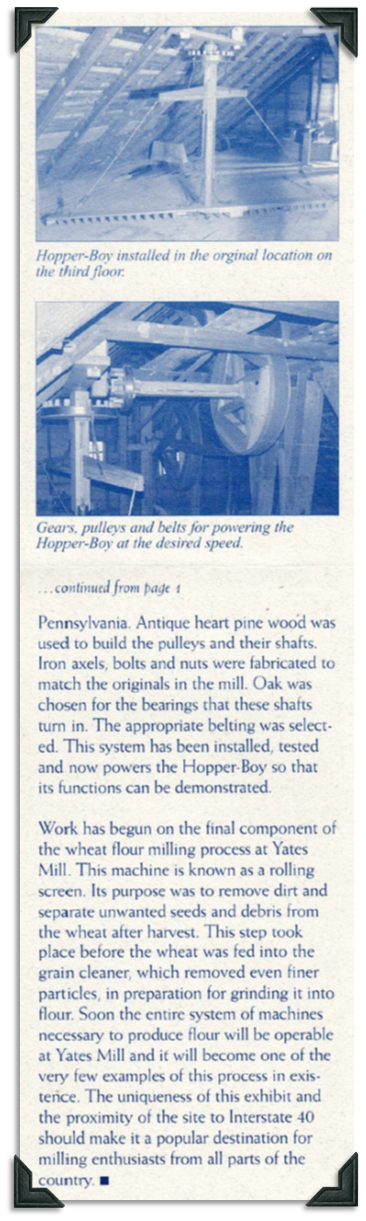

- “Jim Graham” Hopper-Boy Installation Completed by William Robbins

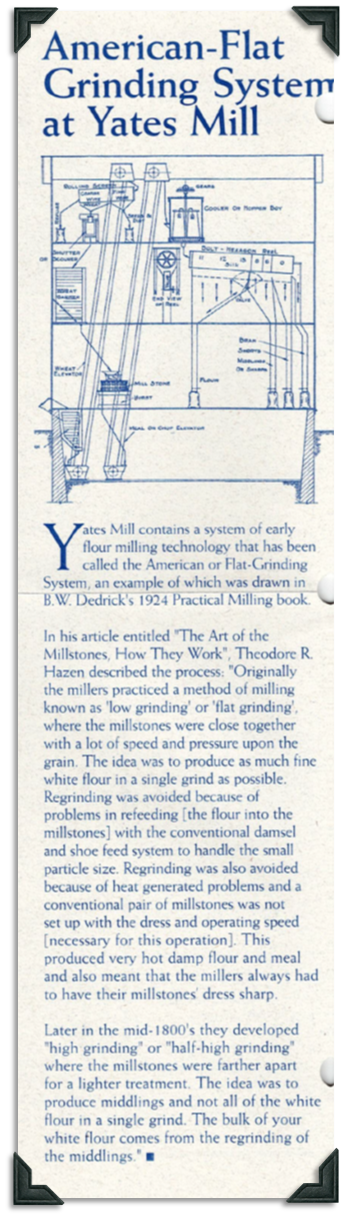

- American-Flat Grinding System at Yates Mill

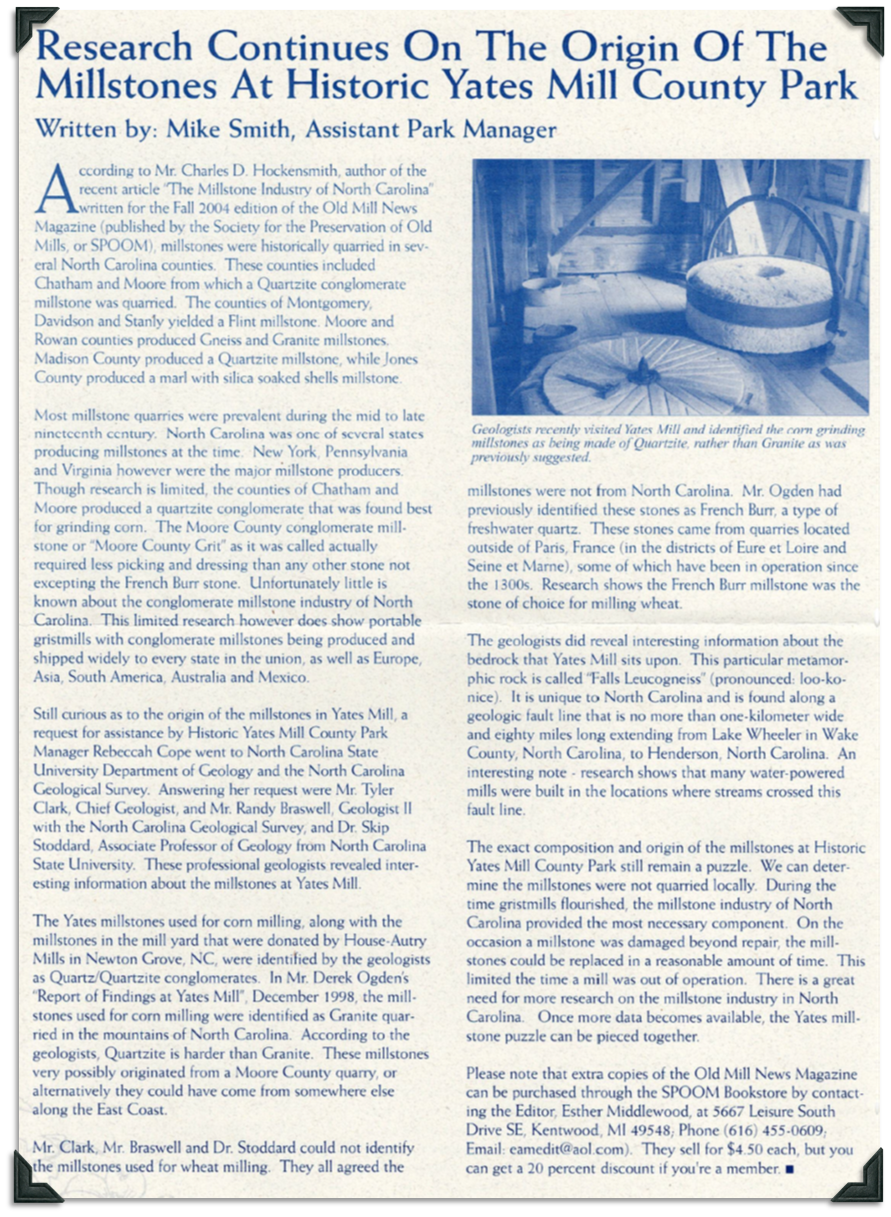

- Research Continues On The Origins Of The Millstones At Historic Yates Mill County Park by Mike Smith

- Restoration of the Flour Milling Process Completed by William Robbins

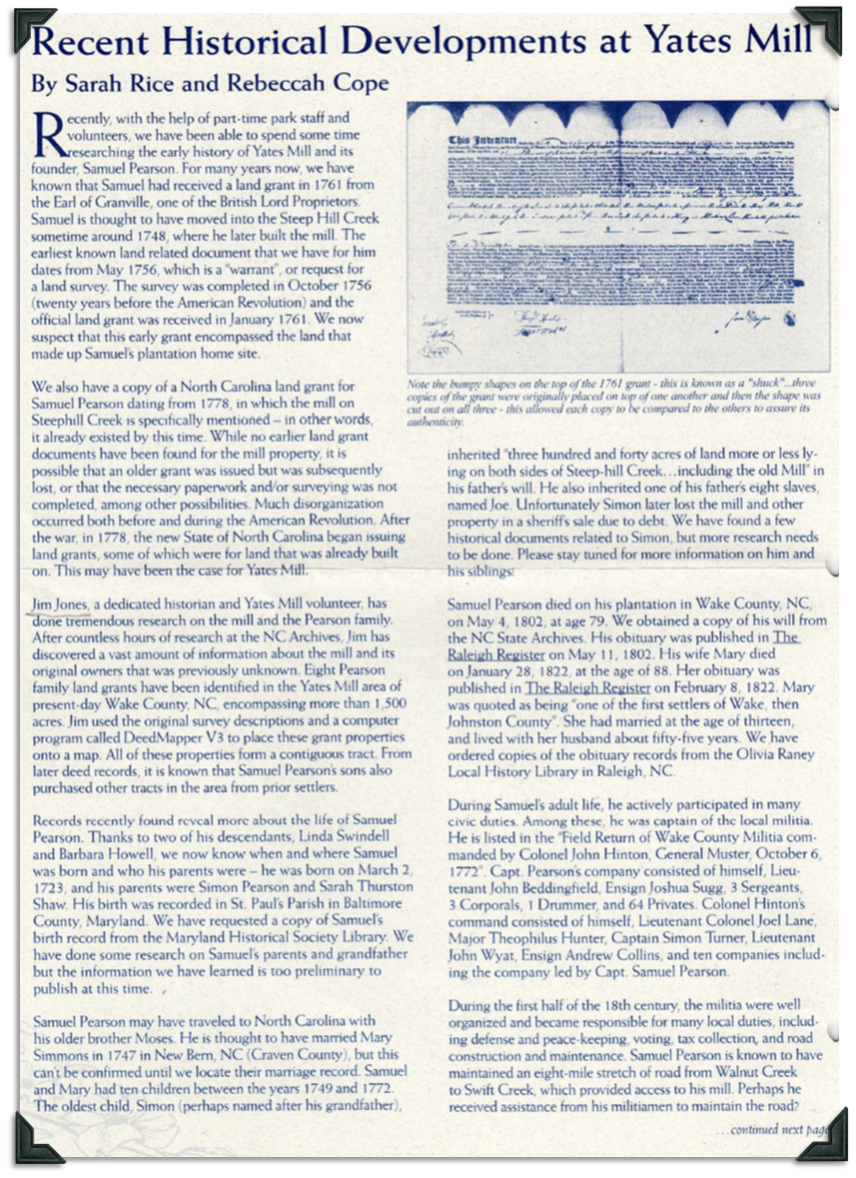

- Recent Historical Developments at Yates Mill by Sarah Rice and Rebeccah Cope

To see more information about the history of Yates Mill and the role Yates Mill Associates played in restoring the mill, visit the A.E. Finley Center at Historic Yates Mill County Park to see displays, view artifacts, and watch videos of the mill in action.