We Need Your Help to Replace the Wheel!

We need to raise $400,000 to keep the wheel turning!

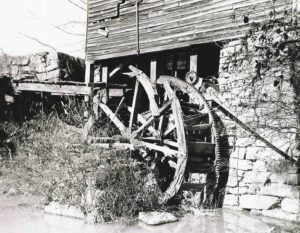

Lasting nearly double its expected lifespan, the waterwheel at Yates Mill is in bad shape and needs to be replaced.

Though we’re proud to work with Wake County and N.C. State University to keep Yates Mill open to you, Yates Mill Associates is solely responsible for financing all the repairs — big and small — that this historic treasure requires.

Please help us keep the wheel turning by making a gift to Yates Mill Associates.

History of the Waterwheel

Over 250 years old, Yates Mill is the last remaining mill of approximately 70 mills that once operated in Wake County. The mill is powered by a 12-foot tall overshot waterwheel supplied by a 24 acre millpond. Originally a gristmill for corn and wheat, it contains an early example of the third federal patent issued in the United States. This patent was issued in 1790, the year the US Patent Office opened, and was granted to inventor Oliver Evans for the “Automated Flour Milling Process.” Yates Mill is one of the only original structures in the United States restored to working condition that contains the original components of this patented process.

In the 1990s, a group of local concerned citizens banded together and volunteered their time and talents to raise money and restore Yates Mill to the working gristmill you see today. The waterwheel currently at Yates Mill was built in 1994 and placed into use in 2001. The estimated life span of the waterwheel was 10-12 years. With care and attention to detail, Yates Mill Associates has kept the wheel turning for over 20 years.

left: In 1993, Jeff Sugg built and donated the waterwheel you see today at Yates Mill.

center: In 1995, the waterwheel was ready to go but the mill still needed to undergo extensive restoration.

right: Yates Mill undergoing restoration in 1999.

Why We Need to Replace the Wheel

All good things must come to an end and the waterwheel is nearing the end of its useful life. Constant repairs need to be made. The spokes of the waterwheel are beginning to slide up and down each time the waterwheel turns and the wood in that area is starting to degrade beyond repair. In the near future, the condition of the waterwheel will be such that turning the waterwheel will become impossible. Because of this, Yates Mill Associates has made the difficult decision to only run the waterwheel during corn grinding weekends, instead of turning the wheel on for each tour of the mill, to hopefully prolong its life until we can raise enough money to replace the waterwheel.

YMA needs $400,000 to replace the waterwheel and surrounding parts. The flume/fore bay must be removed to access the waterwheel and since it is also at the end of its useful life, it will be replaced at the same time as the waterwheel. The current waterwheel will be removed with a crane and shipped to a millwright who specializes in historic waterwheels. Using exact measurements along with historically accurate materials and methods, the waterwheel will be rebuilt in a workshop and shipped back to Raleigh, where it will be reinstalled with a large crane.

We Cannot Do This Without You!

Please visit our Give page to learn how you can support Yates Mill Associates as we work to keep the wheel turning. You can designate that your gift goes directly to our waterwheel campaign.